What are the popular transformer coil product models?

What are the Popular Transformer Coil Product Models?

I. Introduction

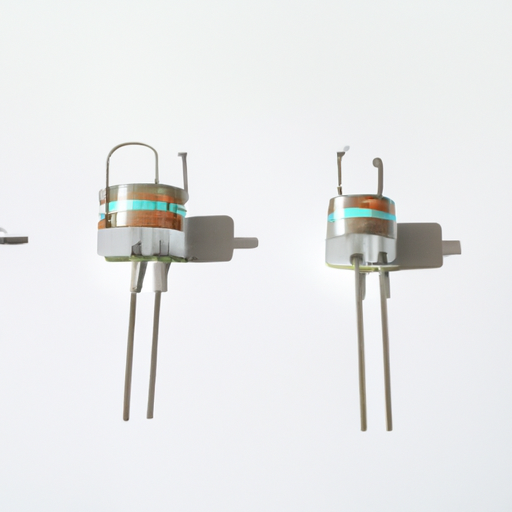

Transformer coils are essential components in electrical systems, playing a crucial role in the transmission and distribution of electrical energy. They are responsible for converting voltage levels, ensuring that electricity can be efficiently delivered from power plants to homes and businesses. This blog post aims to explore popular transformer coil product models, providing insights into their specifications, applications, and the factors influencing their selection.

II. Understanding Transformer Coils

A. Basic Principles of Transformer Operation

At the heart of transformer technology lies the principle of electromagnetic induction. When an alternating current (AC) flows through a coil of wire, it generates a magnetic field. This magnetic field can induce a voltage in a nearby coil, allowing for the transformation of voltage levels. The primary coil receives the input voltage, while the secondary coil delivers the transformed output voltage. The ratio of turns in the coils determines whether the voltage is stepped up or stepped down.

B. Types of Transformer Coils

Transformer coils can be categorized into three main types:

1. **Primary Coils**: These coils receive the input voltage and are connected to the power source.

2. **Secondary Coils**: These coils deliver the transformed voltage to the load.

3. **Tertiary Coils**: Used in some transformers, these coils can provide additional voltage levels or serve specific applications.

C. Materials Used in Transformer Coils

The choice of materials for transformer coils significantly impacts their performance. Common materials include:

1. **Copper vs. Aluminum Windings**: Copper is often preferred for its superior conductivity, while aluminum is lighter and more cost-effective.

2. **Insulation Materials**: High-quality insulation is crucial for preventing electrical losses and ensuring safety. Materials like paper, resin, and various polymers are commonly used.

III. Popular Transformer Coil Product Models

A. Overview of Leading Manufacturers

Several manufacturers dominate the transformer coil market, known for their innovative designs and reliable products. Key players include:

1. **Siemens**

2. **ABB**

3. **Schneider Electric**

4. **General Electric**

B. Detailed Examination of Popular Models

1. Siemens 3-Phase Transformer Coils

Siemens offers a range of 3-phase transformer coils designed for various applications. These coils are known for their high efficiency and reliability.

Specifications and Features: Siemens coils typically feature robust construction, high thermal resistance, and advanced insulation systems.

Applications and Industries Served: Commonly used in industrial settings, these coils are ideal for power generation, distribution, and large-scale manufacturing.

2. ABB Dry-Type Transformer Coils

ABB's dry-type transformer coils are designed for environments where safety and low maintenance are priorities.

Specifications and Features: These coils are compact, lightweight, and feature excellent thermal management. They are also environmentally friendly, as they do not use oil.

Applications and Industries Served: Ideal for commercial buildings, renewable energy applications, and urban installations.

3. Schneider Electric's Modicon Transformer Coils

Schneider Electric's Modicon transformer coils are known for their integration with smart technology.

Specifications and Features: These coils offer advanced monitoring capabilities, allowing for real-time data collection and analysis.

Applications and Industries Served: Suitable for smart grids, industrial automation, and energy management systems.

4. General Electric's Power Transformer Coils

General Electric (GE) provides a wide range of power transformer coils that cater to various voltage levels and applications.

Specifications and Features: GE coils are designed for high performance, featuring advanced cooling systems and robust insulation.

Applications and Industries Served: Commonly used in utility applications, large industrial plants, and renewable energy projects.

C. Comparison of Features and Specifications

When comparing transformer coil models, several factors come into play:

1. **Efficiency Ratings**: Higher efficiency ratings translate to lower energy losses, making them more cost-effective in the long run.

2. **Load Capacities**: The ability to handle varying load demands is crucial for ensuring reliable performance.

3. **Environmental Considerations**: Many manufacturers are now focusing on eco-friendly designs and materials to reduce their environmental impact.

IV. Factors Influencing the Choice of Transformer Coil Models

A. Application Requirements

The choice of transformer coil model often depends on specific application requirements:

1. **Industrial vs. Commercial Use**: Industrial applications may require larger, more robust coils, while commercial settings may prioritize compact designs.

2. **Load Demands and Voltage Levels**: Understanding the load requirements and voltage levels is essential for selecting the appropriate transformer coil.

B. Cost Considerations

Cost is a significant factor in the decision-making process:

1. **Initial Investment vs. Long-Term Savings**: While some models may have a higher upfront cost, their efficiency can lead to substantial savings over time.

2. **Maintenance Costs**: Models that require less maintenance can be more cost-effective in the long run.

C. Regulatory and Safety Standards

Compliance with local and international standards is crucial for ensuring safety and reliability:

1. **Compliance with Local and International Standards**: Manufacturers must adhere to various regulations, which can influence the design and materials used in transformer coils.

2. **Importance of Certifications**: Certifications from recognized organizations can provide assurance of quality and safety.

V. Future Trends in Transformer Coil Technology

A. Innovations in Materials and Design

The transformer coil industry is witnessing significant innovations:

1. **Advances in Insulation Technology**: New insulation materials are being developed to enhance performance and safety.

2. **Use of Smart Technology in Transformers**: Integration of IoT and smart technology is enabling real-time monitoring and predictive maintenance.

B. Sustainability and Environmental Impact

Sustainability is becoming a key focus:

1. **Eco-Friendly Materials and Practices**: Manufacturers are increasingly adopting eco-friendly materials and practices to reduce their carbon footprint.

2. **Energy Efficiency Improvements**: Ongoing research aims to enhance the energy efficiency of transformer coils, contributing to overall energy savings.

C. Market Trends and Forecasts

The transformer coil market is evolving:

1. **Growth in Renewable Energy Applications**: As the demand for renewable energy sources increases, so does the need for efficient transformer coils.

2. **Increasing Demand for Electric Vehicles and Charging Infrastructure**: The rise of electric vehicles is driving the need for advanced transformer technology to support charging stations.

VI. Conclusion

Transformer coils are vital components in electrical systems, facilitating the efficient transmission and distribution of electricity. Understanding the popular product models, their specifications, and applications is essential for making informed decisions. As technology continues to evolve, the future of transformer coil technology looks promising, with innovations aimed at enhancing efficiency, sustainability, and performance.

VII. References

1. Siemens AG. (2023). Transformer Technology. Retrieved from [Siemens Website](https://www.siemens.com)

2. ABB Ltd. (2023). Dry-Type Transformers. Retrieved from [ABB Website](https://global.abb)

3. Schneider Electric. (2023). Modicon Transformer Solutions. Retrieved from [Schneider Electric Website](https://www.se.com)

4. General Electric. (2023). Power Transformer Products. Retrieved from [GE Website](https://www.ge.com)

This blog post serves as a comprehensive guide to understanding popular transformer coil product models, their applications, and the factors influencing their selection in various industries.