What components and modules does a motorcycle coil contain?

What Components and Modules Does a Motorcycle Coil Contain?

I. Introduction

Motorcycles are intricate machines that rely on various components working in harmony to deliver performance and reliability. One of the most critical components in a motorcycle's ignition system is the motorcycle coil. This device plays a pivotal role in converting low voltage from the battery into the high voltage needed to ignite the fuel-air mixture in the engine's cylinders. Understanding the components and modules of a motorcycle coil is essential for any motorcycle enthusiast or owner, as it can significantly impact engine performance and reliability. In this article, we will explore the basic functions, main components, additional modules, types, maintenance, and troubleshooting of motorcycle coils.

II. Basic Function of a Motorcycle Coil

The primary function of a motorcycle coil is to facilitate the ignition process. When the ignition switch is turned on, the battery sends a low voltage current to the primary winding of the coil. This current creates a magnetic field around the coil. When the ignition system triggers the coil to discharge, the magnetic field collapses, inducing a high voltage in the secondary winding. This high voltage is then sent to the spark plug, igniting the fuel-air mixture in the engine. The efficiency of this process is crucial for optimal engine performance, as a weak spark can lead to misfires, reduced power, and increased emissions.

III. Main Components of a Motorcycle Coil

A. Primary Winding

The primary winding is the first coil of wire in the ignition coil. It consists of a relatively small number of turns of copper wire, typically ranging from 100 to 200 turns. The copper wire is chosen for its excellent conductivity, allowing for efficient current flow. The number of turns in the primary winding is significant because it directly affects the magnetic field strength generated when current flows through it. A higher number of turns can produce a stronger magnetic field, which is essential for generating the high voltage needed in the secondary winding.

B. Secondary Winding

The secondary winding is the second coil of wire in the ignition coil and is responsible for generating the high voltage needed to ignite the fuel-air mixture. This winding consists of thousands of turns of wire, often around 10,000 to 30,000 turns. The material used for the secondary winding is also typically copper, which ensures good conductivity. The large number of turns in the secondary winding is crucial because it allows the coil to step up the voltage significantly, often to levels exceeding 20,000 volts. This high voltage is necessary to create a spark that can jump the gap in the spark plug.

C. Core

The core of the motorcycle coil is a critical component that enhances the coil's efficiency. It is usually made from materials like ferrite or laminated iron, which are excellent at conducting magnetic fields. The core serves to concentrate the magnetic field generated by the primary winding, allowing for a more efficient transfer of energy to the secondary winding. The type of core used can affect the coil's performance, with laminated iron cores generally providing better performance due to their ability to reduce energy losses.

D. Insulation

Insulation is vital in a motorcycle coil to prevent short circuits and ensure safe operation. The high voltages generated in the secondary winding can cause arcing if not properly insulated. Common insulation materials used in motorcycle coils include epoxy resin and silicone rubber, which can withstand high temperatures and electrical stress. Proper insulation not only protects the coil's internal components but also enhances the overall reliability of the ignition system.

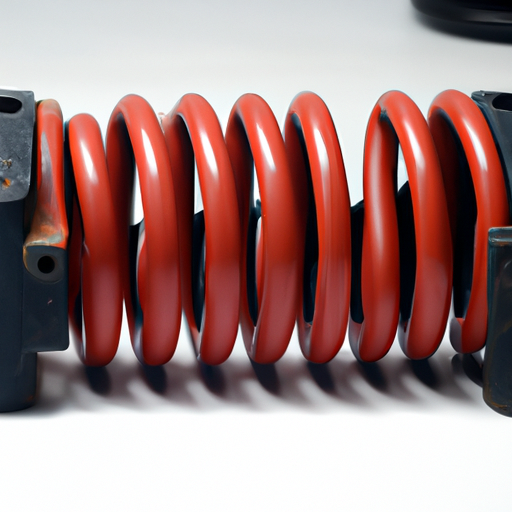

E. Housing

The housing of the motorcycle coil serves multiple purposes. It protects the internal components from environmental factors such as moisture, dirt, and heat. The materials used for the housing are typically durable and heat-resistant, such as plastic or metal. A well-designed housing ensures that the coil can operate effectively in various conditions, contributing to the longevity and reliability of the ignition system.

IV. Additional Modules and Features

A. Ignition Control Module (ICM)

In modern motorcycle ignition systems, the Ignition Control Module (ICM) plays a crucial role. The ICM is responsible for controlling the timing of the spark and ensuring that the ignition occurs at the optimal moment for engine performance. It integrates with the coil to manage the electrical signals sent to the primary winding, allowing for precise control over the ignition process. This integration enhances fuel efficiency and reduces emissions, making it an essential component in contemporary motorcycles.

B. Capacitor Discharge Ignition (CDI)

Capacitor Discharge Ignition (CDI) systems are another advancement in motorcycle ignition technology. In a CDI system, a capacitor stores electrical energy and discharges it rapidly through the coil when needed. This method allows for a more powerful spark and quicker ignition timing, which can improve engine performance, especially in high-performance motorcycles. The interaction between the CDI and the coil is crucial, as the coil must be designed to handle the rapid discharge of energy without overheating or failing.

C. Digital Ignition Systems

Digital ignition systems represent the latest evolution in motorcycle ignition technology. These systems use microprocessors to control the ignition timing and other parameters, allowing for real-time adjustments based on engine conditions. Digital ignition systems offer several benefits over traditional systems, including improved fuel efficiency, reduced emissions, and enhanced performance. The integration of digital technology with the coil allows for more precise control over the ignition process, making it a popular choice for modern motorcycles.

V. Types of Motorcycle Coils

A. Conventional Ignition Coils

Conventional ignition coils are the most common type found in older motorcycles. They consist of a simple design with a primary and secondary winding and are typically used in basic ignition systems. While they are reliable, they may not provide the same level of performance as more advanced coil types.

B. Dual Output Coils

Dual output coils are designed to provide spark to two cylinders simultaneously, making them ideal for V-twin engines. These coils offer the advantage of simplifying the ignition system by reducing the number of coils needed while still delivering adequate spark to both cylinders.

C. Coil-on-Plug (COP) Systems

Coil-on-Plug (COP) systems are a modern innovation where each spark plug has its own dedicated coil mounted directly on top of it. This design eliminates the need for spark plug wires and allows for more efficient energy transfer, resulting in improved performance and reduced emissions. COP systems are becoming increasingly popular in contemporary motorcycles.

D. High-Performance Coils

High-performance coils are designed for racing and high-performance applications. They typically feature enhanced materials and designs that allow for higher voltage output and faster response times. These coils can significantly improve engine performance, making them a popular choice among motorcycle enthusiasts and racers.

VI. Maintenance and Troubleshooting

A. Signs of a Failing Coil

Recognizing the signs of a failing coil is crucial for maintaining optimal engine performance. Common symptoms include difficulty starting the motorcycle, misfires, reduced power, and increased fuel consumption. If you notice any of these issues, it may be time to inspect the ignition coil.

B. Testing the Coil

Testing the motorcycle coil is a straightforward process that can be done with a multimeter. To test the coil, you will need to measure the resistance of both the primary and secondary windings. The specific resistance values can vary by manufacturer, so it's essential to consult the motorcycle's service manual for the correct specifications. A significant deviation from these values may indicate a faulty coil.

C. Replacement Considerations

If a coil is determined to be faulty, replacing it is often the best course of action. When choosing a replacement coil, it's essential to select one that is compatible with your motorcycle's make and model. Additionally, consider the type of coil that best suits your riding style, whether it's a conventional coil for everyday use or a high-performance coil for racing.

VII. Conclusion

In conclusion, the motorcycle coil is a vital component of the ignition system, playing a crucial role in engine performance and reliability. Understanding its components, functions, and types can help motorcycle owners maintain their machines effectively. Regular maintenance and timely replacement of faulty coils can prevent performance issues and ensure a smooth riding experience. As technology continues to evolve, staying informed about advancements in ignition systems will empower motorcycle enthusiasts to make educated decisions about their machines. Whether you're a seasoned rider or a newcomer to the world of motorcycles, a deeper understanding of the motorcycle coil will enhance your appreciation for these remarkable machines.

VIII. References

For further reading and exploration of motorcycle coils and ignition systems, consider the following resources:

1. Motorcycle Mechanics: A Comprehensive Guide

2. The Art of Motorcycle Maintenance

3. Motorcycle Electrical Systems: A Practical Guide

4. Online forums and communities dedicated to motorcycle maintenance and repair.

By delving into these resources, you can expand your knowledge and skills in motorcycle mechanics, ensuring a more enjoyable and reliable riding experience.