What components and modules does the stator coil contain?

What Components and Modules Does the Stator Coil Contain?

I. Introduction

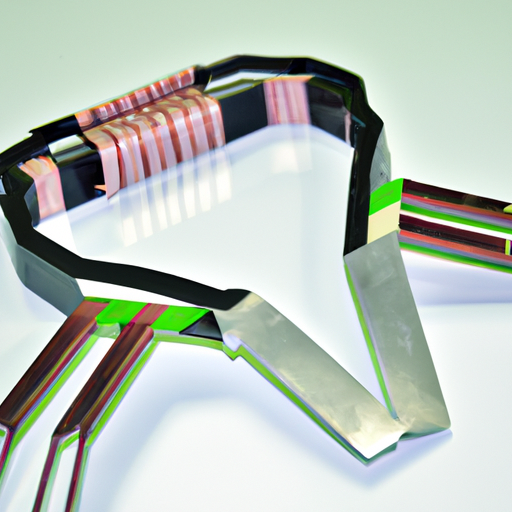

The stator coil is a fundamental component in various electrical machines, including motors and generators. It plays a crucial role in the conversion of electrical energy into mechanical energy and vice versa. Understanding the components and modules that make up the stator coil is essential for engineers and technicians working in the field of electrical engineering. This blog post will delve into the basic structure of the stator coil, its key components, associated modules, manufacturing processes, applications, and future trends in stator coil technology.

II. Basic Structure of the Stator Coil

A. Description of the Stator

The stator is the stationary part of an electric motor or generator, contrasting with the rotor, which rotates. In electric motors, the stator generates a magnetic field that interacts with the rotor to produce motion. In generators, the stator captures the mechanical energy produced by the rotor and converts it into electrical energy. The design and configuration of the stator are critical for the efficiency and performance of the machine.

B. Overview of Coil Configuration

The stator coil is typically configured in various winding types, such as lap and wave windings. The choice of winding type affects the machine's performance characteristics, including torque and efficiency. Additionally, the number of turns and layers in the coil influences the magnetic field strength and the overall output of the machine.

III. Key Components of the Stator Coil

A. Conductors

The conductors in the stator coil are responsible for carrying electrical current. The most common materials used for conductors are copper and aluminum. Copper is preferred for its excellent conductivity and durability, while aluminum is lighter and more cost-effective. Insulation materials are also critical, as they prevent short circuits and ensure safe operation. Common insulation materials include enamel coatings and thermosetting resins.

B. Core Material

The core material of the stator coil is essential for enhancing the magnetic flux. Silicon steel and laminated steel are commonly used due to their magnetic properties. The core's design minimizes energy losses due to eddy currents, which can significantly impact the efficiency of the machine. A well-designed core allows for better magnetic field concentration, leading to improved performance.

C. Insulation System

The insulation system is vital for the performance and safety of the stator coil. Different classes of insulation, such as Class A, B, F, and H, indicate the temperature ratings and thermal endurance of the materials used. Proper insulation ensures that the stator coil can operate under high temperatures without degrading, thus prolonging the lifespan of the electrical machine.

IV. Modules Associated with the Stator Coil

A. Winding Modules

Stator coils can be configured in single-phase or three-phase windings, depending on the application. Three-phase windings are commonly used in industrial motors due to their efficiency and smooth operation. The connection configurations, such as star (Y) and delta (Δ), also play a significant role in the performance of the motor. Each configuration has its advantages and is chosen based on the specific requirements of the application.

B. Cooling Modules

Thermal management is crucial for the longevity and efficiency of the stator coil. Cooling modules can be categorized into air cooling and liquid cooling systems. Air cooling is simpler and more cost-effective, while liquid cooling is more efficient for high-power applications. Effective cooling prevents overheating, which can lead to insulation failure and reduced performance.

C. Sensor Modules

Modern stator coils often incorporate sensor modules to monitor performance. Temperature sensors help detect overheating, while vibration sensors can identify mechanical issues. These sensors provide real-time data, allowing for proactive maintenance and improved reliability of the electrical machine.

V. Manufacturing and Assembly of Stator Coils

A. Winding Process

The winding process is a critical step in the manufacturing of stator coils. It can be performed using automated or manual techniques. Automated winding machines ensure precision and consistency, while manual winding may be used for custom applications. Quality control measures are essential during this process to ensure that the coils meet the required specifications.

B. Assembly of Components

Once the winding is complete, the assembly of components begins. This involves joining the conductors to the core and applying insulation materials. Proper assembly techniques are crucial to ensure that the stator coil functions effectively and safely.

C. Testing and Quality Assurance

Testing and quality assurance are vital to ensure the reliability of the stator coil. Electrical testing checks for short circuits and insulation integrity, while mechanical testing assesses the structural integrity of the assembly. These tests help identify any potential issues before the stator coil is put into operation.

VI. Applications of Stator Coils

A. Electric Motors

Stator coils are integral to various types of electric motors, including induction and synchronous motors. Induction motors are widely used in industrial applications due to their robustness and simplicity, while synchronous motors offer precise speed control and efficiency.

B. Generators

In generators, stator coils play a crucial role in converting mechanical energy into electrical energy. AC generators and DC generators utilize stator coils to produce electricity, making them essential in power generation systems.

C. Transformers

Stator coils are also found in transformers, where they help transfer electrical energy between circuits. The design and configuration of the stator coil in transformers are critical for efficient energy transfer and voltage regulation.

VII. Conclusion

In summary, the stator coil is a vital component in electrical machines, comprising various components and modules that contribute to its performance and efficiency. Understanding the structure, key components, associated modules, and manufacturing processes of stator coils is essential for engineers and technicians in the field. As technology advances, future trends in stator coil design and materials will likely focus on improving efficiency, reducing costs, and enhancing performance. A thorough understanding of stator coil components is crucial for anyone involved in the design, manufacturing, or maintenance of electrical machines.

VIII. References

- Academic Journals on Electrical Engineering

- Industry Standards for Electrical Machines

- Textbooks on Electrical Engineering Principles and Applications

This blog post provides a comprehensive overview of the components and modules that make up the stator coil, ensuring that readers gain a solid understanding of this essential element in electrical machines.