The latest coil specifications

The Latest Coil Specifications

I. Introduction

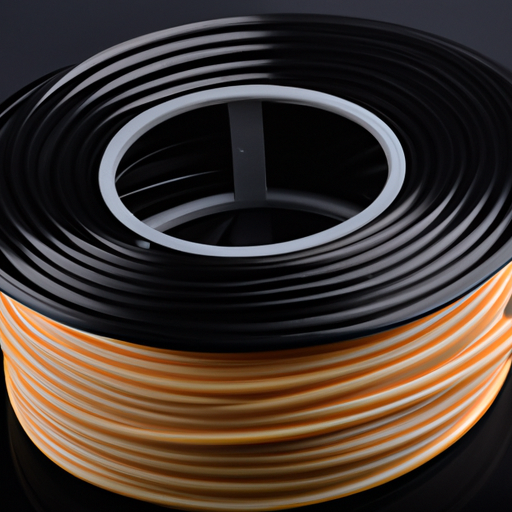

A. Definition of Coils

Coils are essential components in various electrical and mechanical systems, characterized by their coiled wire structure. They serve multiple functions, including energy storage, magnetic field generation, and mechanical support. In electrical applications, coils are primarily used in inductors and transformers, while in mechanical contexts, they can be found in springs and heat exchangers. The versatility of coils makes them integral to the functionality of countless devices across different industries.

B. Purpose of the Document

This document aims to provide an overview of the latest coil specifications, highlighting their significance in modern technology. By understanding these specifications, readers can appreciate the role coils play in enhancing performance, safety, and efficiency in various applications.

II. Types of Coils

A. Electrical Coils

1. **Inductors**: Inductors are passive electrical components that store energy in a magnetic field when electrical current flows through them. They are widely used in filters, oscillators, and power supply circuits.

2. **Transformers**: Transformers are devices that transfer electrical energy between two or more circuits through electromagnetic induction. They are crucial for voltage regulation and power distribution in electrical systems.

B. Mechanical Coils

1. **Springs**: Mechanical coils, such as springs, store mechanical energy and are used in various applications, from automotive suspensions to household items like pens.

2. **Heat Exchangers**: Coils in heat exchangers facilitate the transfer of heat between two or more fluids, playing a vital role in heating and cooling systems.

C. Specialty Coils

1. **RF Coils**: Radio frequency (RF) coils are designed for use in RF applications, such as antennas and RF amplifiers, where they help in tuning and signal processing.

2. **Air Coils**: Air coils are inductors that do not use a magnetic core, making them suitable for high-frequency applications due to their low losses.

III. Key Specifications of Coils

A. Material Composition

1. **Common Materials Used**: The most common materials for coil construction include copper and aluminum. Copper is favored for its excellent electrical conductivity, while aluminum is lighter and more cost-effective.

2. **Impact of Material on Performance**: The choice of material significantly affects the coil's performance, including its resistance, inductance, and thermal properties. For instance, copper coils generally exhibit lower resistance, leading to higher efficiency.

B. Dimensions and Tolerances

1. **Wire Gauge and Diameter**: The wire gauge used in coils affects their electrical characteristics. Thicker wires can carry more current but may also increase the coil's size and weight.

2. **Length, Width, and Height Specifications**: Coils must adhere to specific dimensional tolerances to ensure compatibility with other components and to meet performance requirements.

C. Electrical Characteristics

1. **Inductance and Resistance**: Inductance is a measure of a coil's ability to store energy in a magnetic field, while resistance affects how much current can flow through the coil. Both parameters are critical for determining a coil's suitability for a given application.

2. **Current Rating and Voltage Rating**: Coils are rated for maximum current and voltage levels to prevent overheating and failure. Understanding these ratings is essential for safe and effective coil usage.

D. Thermal Properties

1. **Operating Temperature Range**: Coils must operate within specific temperature ranges to maintain performance and reliability. Exceeding these limits can lead to insulation breakdown and coil failure.

2. **Heat Dissipation Capabilities**: Effective heat dissipation is crucial for maintaining coil performance, especially in high-power applications. Coils designed with better thermal management can operate more efficiently and have longer lifespans.

IV. Industry Standards and Certifications

A. Overview of Relevant Standards

1. **ISO Standards**: The International Organization for Standardization (ISO) provides guidelines for manufacturing and testing coils, ensuring quality and safety across industries.

2. **ASTM Specifications**: The American Society for Testing and Materials (ASTM) sets standards for materials and testing methods, which are crucial for ensuring the reliability of coil components.

B. Importance of Compliance

1. **Safety Considerations**: Compliance with industry standards helps mitigate risks associated with electrical and mechanical failures, ensuring the safety of both users and equipment.

2. **Quality Assurance**: Adhering to established specifications guarantees that coils meet performance expectations, leading to higher customer satisfaction and reduced warranty claims.

V. Recent Innovations in Coil Technology

A. Advances in Materials

1. **Use of Superconductors**: The development of superconducting materials has led to coils that can operate with zero electrical resistance, significantly improving efficiency in applications like magnetic resonance imaging (MRI) and particle accelerators.

2. **Development of Composite Materials**: Innovations in composite materials have resulted in lighter and more durable coils, enhancing performance in various applications, including aerospace and automotive industries.

B. Design Improvements

1. **Miniaturization of Coils**: Advances in manufacturing techniques have enabled the production of smaller coils without compromising performance, making them ideal for compact electronic devices.

2. **Enhanced Efficiency and Performance**: New design methodologies, such as computer-aided design (CAD) and simulation tools, allow for the optimization of coil geometries, leading to improved efficiency and performance.

C. Applications of New Technologies

1. **Electric Vehicles**: Coils play a crucial role in electric vehicles, where they are used in motors, charging systems, and energy storage solutions.

2. **Renewable Energy Systems**: Coils are integral to renewable energy technologies, such as wind turbines and solar inverters, where they help convert and manage electrical energy.

VI. Applications of Coils

A. Automotive Industry

Coils are vital in the automotive sector, particularly in electric motors and sensors. They enable efficient energy conversion and play a role in various vehicle systems, including ignition and power steering.

B. Consumer Electronics

In consumer electronics, coils are found in smartphones, laptops, and other devices, where they are used for power management, signal processing, and wireless charging.

C. Industrial Equipment

Coils are extensively used in industrial equipment, facilitating automation and manufacturing processes. They are integral to systems such as conveyor belts, robotic arms, and control systems.

VII. Challenges and Considerations

A. Manufacturing Challenges

1. **Precision in Production**: Achieving the required precision in coil manufacturing is critical for performance. Variations in dimensions or material properties can lead to inefficiencies and failures.

2. **Cost Implications**: The cost of high-quality materials and advanced manufacturing techniques can be significant, impacting the overall pricing of coil-based products.

B. Environmental Considerations

1. **Sustainability of Materials**: The sourcing and use of materials for coils raise sustainability concerns. Manufacturers are increasingly looking for eco-friendly alternatives and practices.

2. **Recycling and Disposal Issues**: As technology evolves, the disposal and recycling of coils become more critical. Developing efficient recycling methods can help mitigate environmental impacts.

VIII. Conclusion

A. Summary of Key Points

Coils are fundamental components in various industries, with specifications that significantly impact their performance and application. Understanding the latest coil specifications, including material composition, dimensions, electrical characteristics, and industry standards, is essential for optimizing their use.

B. Future Trends in Coil Specifications

1. **Predictions for the Next Decade**: As technology continues to advance, we can expect further innovations in coil materials and designs, leading to enhanced performance and efficiency.

2. **Importance of Ongoing Research and Development**: Continuous research and development will be crucial in addressing the challenges faced by the coil industry, ensuring that coils remain relevant and effective in meeting the demands of modern technology.

IX. References

A comprehensive list of sources and further reading materials, including industry publications and standards documents, can provide additional insights into the latest coil specifications and technologies.

---

This blog post provides a detailed overview of the latest coil specifications, emphasizing their importance across various industries and the innovations shaping their future. By understanding these specifications, readers can better appreciate the role coils play in modern technology.